Systematics

1

2

1

2

With model series DMC 200-1 to 840-3 JWE-BANSS utilizes international experience and the latest scientific findings in the development of continuous dehairing machines. After pre-scalding has been completed using either a scalding tunnel or the scalding tank, the pigs are brought through into the dehairing machine by means of introduction chute.

Scalding with 60 °C (140 °F) hot water is constantly occurring with the dehairing process. After the dehairing process has been finished the ejection slide opens automatically and the carcass reaches the receiving plate conveyor or table.

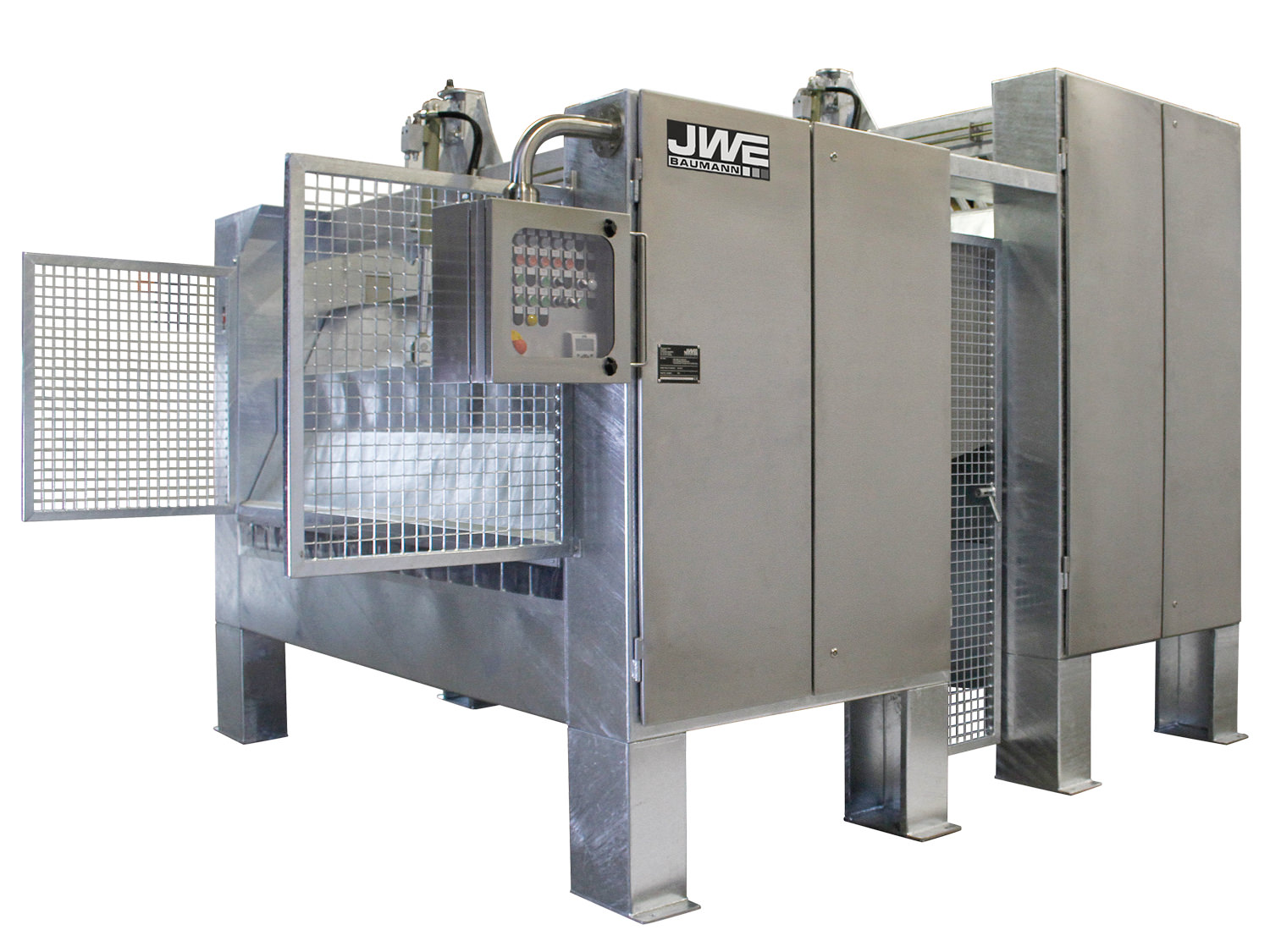

In this regard JWE-Baumann offers a wide range of machines such as pre-cleaning machines (1) and whipping machines (2).

Continuous dehairing machine

| No. | Type | Pigs/h | Polishing roller | A | B | C | D |

| 7080100004 | DMC-220-1 | 240 | 6,740 mm | 2,100 mm | 8,155 mm | 4,410 mm | |

| 7080100005 | DMC-230-1 | 280 | 7,540 mm | 2,100 mm | 8,955 mm | 4,410 mm | |

| 7080100006 | DMC-240-1 | 320 | 8,340 mm | 2,100 mm | 9,755 mm | 4,410 mm | |

| 7080100007 | DMC-250-1 | 350 | 9,140 mm | 2,100 mm | 10,555 mm | 4,410 mm | |

| 7080100011 | DMC-220-2 | 400 | ■ | 6,740 mm | 2,100 mm | 8,155 mm | 4,410 mm |

| 7080100012 | DMC-230-2 | 460 | ■ | 7,540 mm | 2,100 mm | 8,955 mm | 4,410 mm |

| 7080100013 | DMC-240-2 | 520 | ■ | 8,340 mm | 2,100 mm | 9,755 mm | 4,410 mm |

| 7080100014 | DMC-250-2 | 580 | ■ | 9,140 mm | 2,100 mm | 10,555 mm | 4,410 mm |

| 7080100015 | DMC-260-2 | 640 | ■ | 9,940 mm | 2,100 mm | 11,355 mm | 4,410 mm |

DMC – inlet section

Machine body:

Hygienic frame construction made of sheet metal and profiled parts, stainless steel 1.4301

2 stainless steel maintenance doors on both sides, insulated, to reach of the depilatory area

Maintenance and cleaning flaps on one side to reach the Water tub

Support segments, hot-dip galvanised, with which the dehairing of pigs is possible from a minimum weight of 50 kg

Main dehairing roller, hot-dip galvanised, D457 mm, equipped with dehairing beaters with scraper

Drive motor

Pneumatically actuated jam slide for ejection timing

Special water spraying device made of stainless steel for after- brewing and after-cleaning of the animal body incl. pneumatic closing unit with which the Spraying device can be opened and closed

Piping Water spray device made of stainless steel

Water tank:

Hygienic sheet metal construction made of 1.4301 stainless steel

Heating via built-in steam lance, incl. pneumatic steam control valve and strainer

Water circulation pump

Level limit switch for minimum and maximum water level

Temperature control system for setting the water temperature at 0.5 degrees Accuracy

DMC – outlet part

Machine body:

Hygienic frame construction made of sheet metal and profile parts, stainless steel 1.4301

2 stainless steel maintenance doors on both sides, insulated, to reach the Depilation area

Maintenance and cleaning flaps on one side to reach the Water tub

Support segments, hot-dip galvanised, with which the dehairing of pigs is possible from a minimum weight of 50 kg

Main dehairing roller, hot-dip galvanised, D457 mm, equipped with dehairing beaters with scraper

Drive motor

Pneumatically actuated jam slide for ejection timing

Special water spraying device made of stainless steel for after- brewing and after- cleaning of the animal body incl. pneumatic closing unit with which the Spraying device can be opened and closed

Piping Water spray device made of stainless steel

Water tank:

Hygienic sheet metal construction made of 1.4301 stainless steel

Heating via built-in steam lance, incl. pneumatic steam control valve and strainer

Water circulation pump

Temperature control system for setting the water temperature at 0.5 degrees Accuracy

Connected via pipe connection to the water tub of the DMC Inlet section

Bristle transport:

Hygienic sheet metal construction made of 1.4301 stainless steel

Drive station with drive motor

Deflection station

Cleaning device at the drive station with spray nozzles

Round link chain equipped with specially designed bristle separator strips

Bristle ejection under the drive station

Intermediate slide:

Hygienic sheet metal construction made of 1.4301 stainless steel

As connecting element between inlet and outlet part

Maintenance opening via removable cover

Control:

Stainless steel operating housing

Switch box housing made of stainless steel

Siemens S7 control

Options

Polishing and dehairing roller, hot-dip galvanised, D168 mm, equipped with dehairing beaters with scraper

Drive motor

CONTINUOUS DEHAIRING MACHINE

| No. | Type | Pigs/h | Polishing roller | A | B | C | D |

| 7080100001 | DMC-110-1 | 120 | 3,150 mm | 2,100 mm | 4,655 mm | 4,110 mm | |

| 7080100002 | DMC-120-1 | 160 | 3,950 mm | 2,100 mm | 5,455 mm | 4,110 mm | |

| 7080100003 | DMC-130-1 | 200 | 4,750 mm | 2,100 mm | 6,255 mm | 4,110 mm | |

| 7080100008 | DMC-110-2 | 200 | ■ | 3,150 mm | 2,100 mm | 4,655 mm | 4,110 mm |

| 7080100009 | DMC-120-2 | 260 | ■ | 3,950 mm | 2,100 mm | 5,455 mm | 4,110 mm |

| 7080100010 | DMC-130-2 | 320 | ■ | 4,750 mm | 2,100 mm | 6,255 mm | 4,110 mm |

Specifications

Machine body:

Hygienic frame construction made of sheet metal and profiled parts, stainless steel 1.4301

On both sides 2 maintenance doors made of stainless steel, insulated, to reach the dehairing area

Maintenance and cleaning flaps on one side for reaching the water tank

Supporting segments, hot-dip galvanised, with which the dehairing of pigs from a minimum weight of 50 kg

Main dehairing roller, hot-dip galvanised, D457 mm, equipped with dehairing with scraper

Drive motor

Pneumatically actuated slider for ejecting the dehairing roller

Special stainless steel water spraying device for scalding and cleaning the and cleaning of the animal carcasses, incl. pneumatic closing unit with which the

The spraying device can be opened and closed

Pipework for water spraying device made of stainless steel

Water tank:

Hygienic sheet metal construction made of stainless steel 1.4301

Heating via built-in steam lance, incl. pneumatic steam regulating valve valve and dirt trap

1 water circulation pump

Level limit switch for minimum and maximum water level

Temperature control system for setting the water temperature with 0.5 degree accuracy

Bristle transport:

Hygienic sheet metal construction made of stainless steel 1.4301

Drive station with drive motor

Deflector station

Cleaning device at the drive station with spray nozzles

Round link chain equipped with specially designed bristle separator strips

Bristle discharge under the drive station

Control:

Control box housing made of stainless steel

Switch box housing made of stainless steel

Siemens S7 control system

Options

Polishing and dehairing roller, hot-dip galvanised, D168 mm, equipped with dehairing beaters with scraper

Drive motor

Two-Roll Dehairing Machine

The JWE DM 82 is a two-roll dehairing machine for up to 200 pigs an hour.

| No. | Type | Pigs/h | A | B | C | D | E |

| 7080460001 | DM 82-25 | 200 | 2,500 mm | 3,220 mm | 3,125 mm | 2,990 mm | 4,020 mm |

Specifications

Automatically operating

Machine body steel construction stainless steel

Closed ejection flap, separating the dirty area from the clean area

Dehairing roll Ø 700 mm is equipped with JWE dehairing rubber beater with special metal elements

Dehairing roll Ø 400 mm is equipped with slightly bent JWE dehairing beaters

Retainer ribs for dehairing pigs weighing more than 25 kg

Direct drive

11,0 kW and 5,5 kW

Options

Singeing:

The optional singeing with 12 installed gas burners can be used with

natural gas or

propane gas.

Bristle conveyor:

In a scalding and dehairing combination with two two-roll dehairing machines a bristle conveyor is installed. The conveyor automatically transports bristles and claws to the front.

Two-Roll Dehairing Machine

The JWE DM 80 is a two-roll dehairing machine for up to 120 pigs an hour.

| No. | Type | Pigs/h | A | B | C | D | E |

| 7080440001 | DM 80-20 | 60 | 2,000 mm | 1,310 mm | 2,625 mm | 2,810 mm | 1,830 mm |

| 7080440002 | DM 80-25 | 120 | 2,500 mm | 1,310 mm | 3,125 mm | 2,810 mm | 1,830 mm |

Specifications

Automatically operating

Machine body steel construction stainless steel

Closed ejection flap, separating the dirty area from the clean area

Dehairing roll Ø 700 mm is equipped with JWE dehairing rubber beater with special metal elements

Dehairing roll Ø 400 mm is equipped with slightly bent JWE dehairing beaters

Retainer ribs for dehairing pigs weighing more than 25 kg

Direct drive

11,0 kW and 5,5 kW

Options

Singeing:

The optional singeing in the two-roll dehairing machine can be used with

natural gas or

propane gas.

Depending on the passage width nine or twelve gas burners are installed.

Two-Roll Dehairing Machine

The JWE DM 50-60 is a two-roll dehairing machine for up to 100 pigs an hour.

| No. | Type | Pigs/h | A | B | C | D | E |

| 7080420001 | DM 50-20 | 50 | 2,000 mm | 1,200 mm | 2,625 mm | 2,490 mm | 1,735 mm |

| 7080420002 | DM 50-25 | 100 | 2,500 mm | 1,200 mm | 2,625 mm | 2,490 mm | 1,735 mm |

Specifications

Automatically operating

Machine body steel construction stainless steel

Closed ejection flap, separating the dirty area from the clean area

Dehairing roll Ø 700 mm is equipped with JWE dehairing rubber beater with special metal elements

Dehairing roll Ø 400 mm is equipped with slightly bent JWE dehairing beaters

Retainer ribs for dehairing pigs weighing more than 25 kg

Chain-drive

Drive gear motor 7,5 kW

Options

Singeing:

The optional singeing in the two-roll dehairing machine can be used with

natural gas or

propane gas.

Depending on the passage width nine or twelve gas burners are installed.

Two-Roll Dehairing Machine

The JWE DM 16 is a two-roll dehairing machine for up to 25 pigs an hour.

| No. | Type | Pigs/h | A | B | C | D |

| 7080400003 | DM 16-20 | 25 | 2,000 mm | 970 mm | 2,420 mm | 1,290 mm |

Specifications

Manually operating

Machine body steel construction stainless steel

Closed ejection flap, separating the dirty area from the clean area

Two dehairing rolls are equipped with slightly bent JWE dehairing beaters

Ejection rake operate together with the ejection flap

Chain-drive

Drive gear motor 3,0 kW

Options

Singeing:

The optional singeing in the two-roll dehairing machine can be used with

natural gas or

propane gas.