Condensation scalding

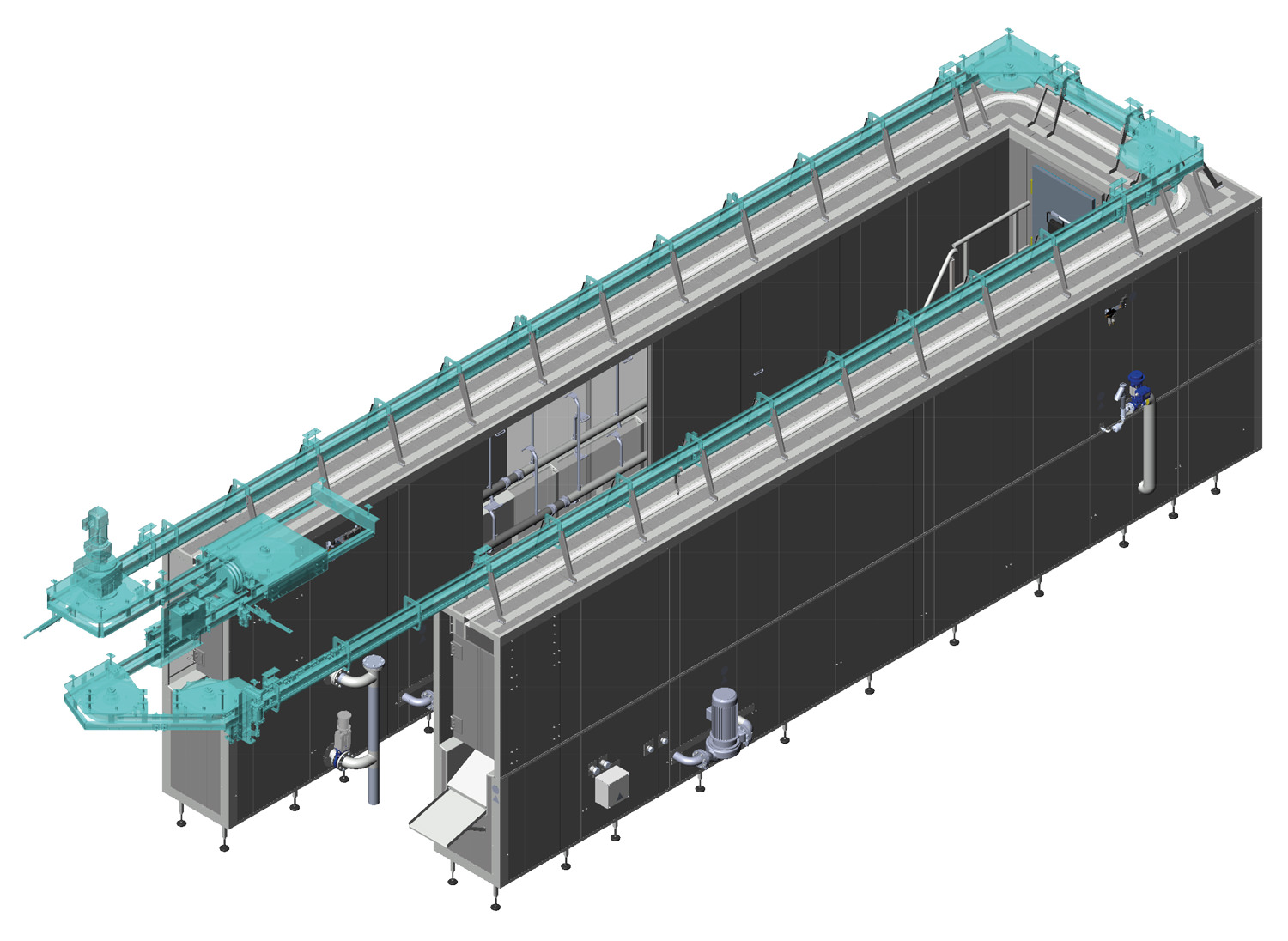

Scalding is carried out with 60 °C (140 °F) warm humid air instead of water. The scalding equipment is constructed in a sandwich construction style and insulated. There is a fully accessible stainless steel tank located at the bottom of the scalding tunnel. Air deflector plates are installed on the interior walls. Fans are aspirating the air in the upper part of the tunnel and circulate this air in exterior channels. During this operation the air is moistened and heated by water vapor. The fans blow the heated air through the lower part back to the scalding tunnel. The air deflector plates push the heated air onto the carcasses where water vapor condenses which creates the scalding effect.

To avoid any risk of corrosion in the scalding tunnel, the conveying system has been installed outside of the scalding tunnel; based on a patent registered design. The looped chains for the carcasses are introduced through a slot in the celling of the scalding channel that is sealed with brushes. There are insulated doors allowing access to the tunnel. Proven and reliable control units perform the process and the automatic temperature control.

| No. | Type | Module | Length | Width |

| 7060100002 | SCM-CT-120-B | Basic module | 1,200 mm | 945 mm |

| 7060100003 | SCM-CT-240-B | Basic module | 2,400 mm | 945 mm |

| 7060100007 | SCM-CT-150-I | Insertion | 1,540 mm | 945 mm |

| 7060100006 | SCM-CT-150-D | Discharge unit | 1,540 mm | 945 mm |

| 7060100008 | SMC-CT-90-C | Corner module | 1,250 mm, 90 degrees | 1,250 mm |

| 7060100004 | SCM-CT-120-V | Ventilation module | 1,200 mm | 2,140 mm |

| 7060100009 | SMC-CT-240-C | Ventilation module | 2,445 mm | 2,390 mm |

| 7060100005 | SCM-CT-120-M | Maintanced module | 2,400 mm | 945 mm |

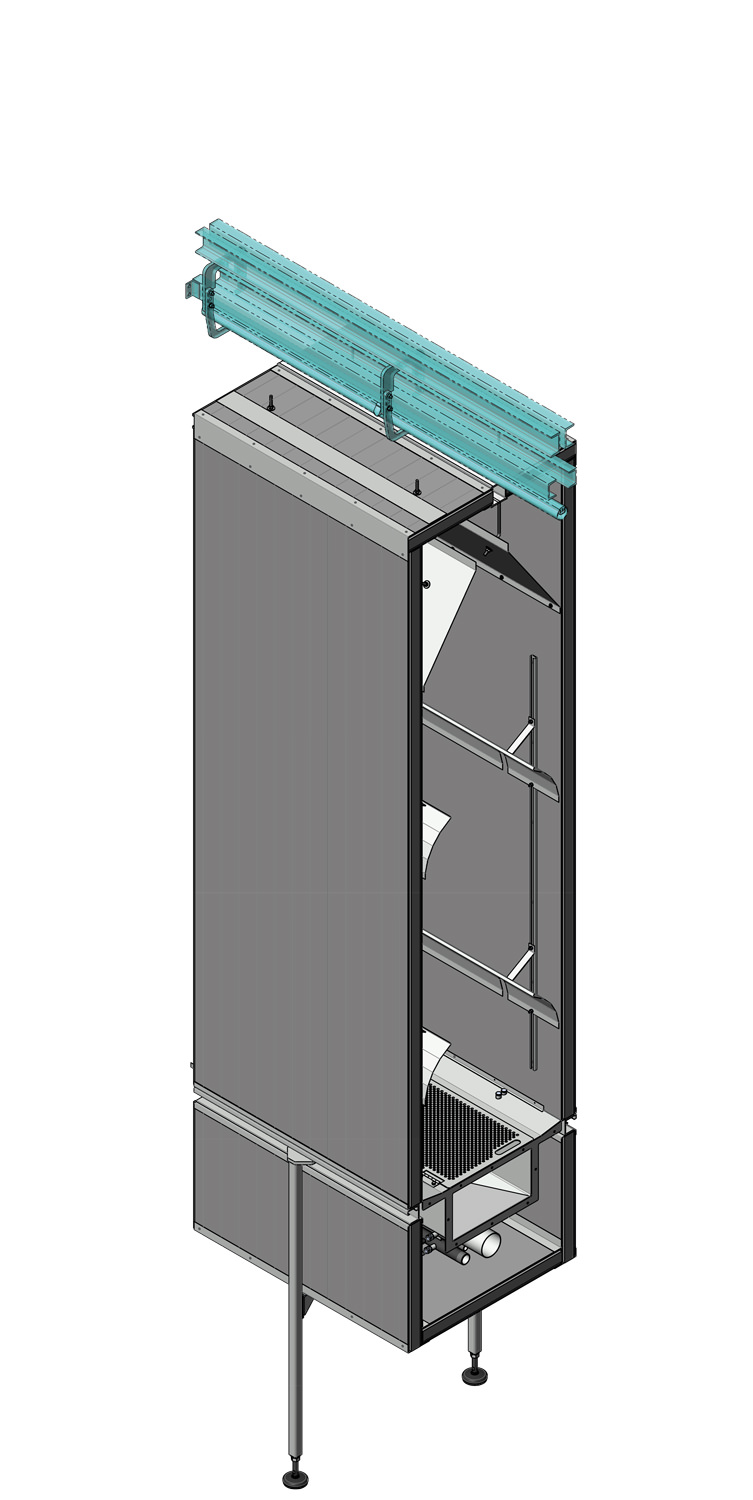

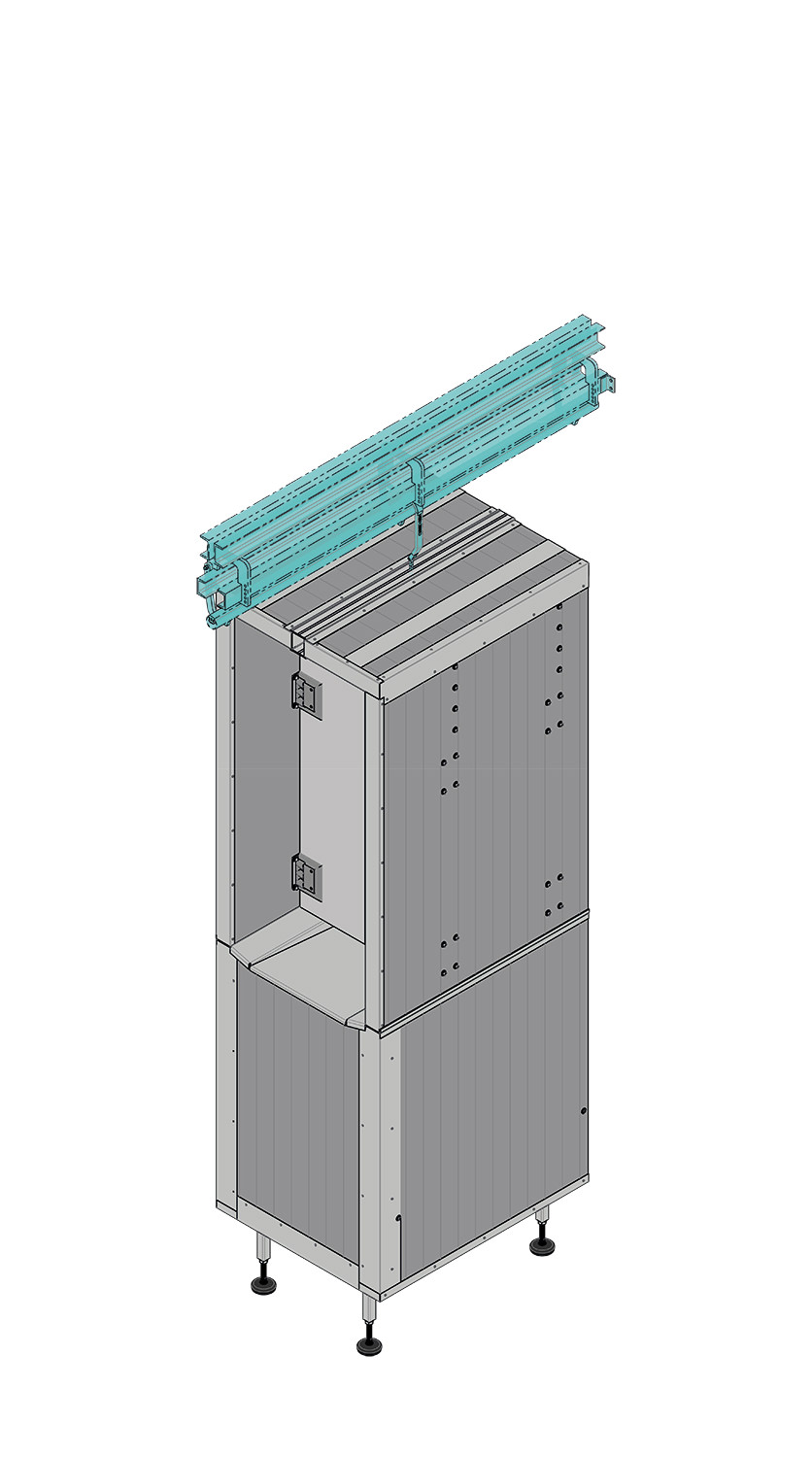

SCM-CT-120-B – Basic module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

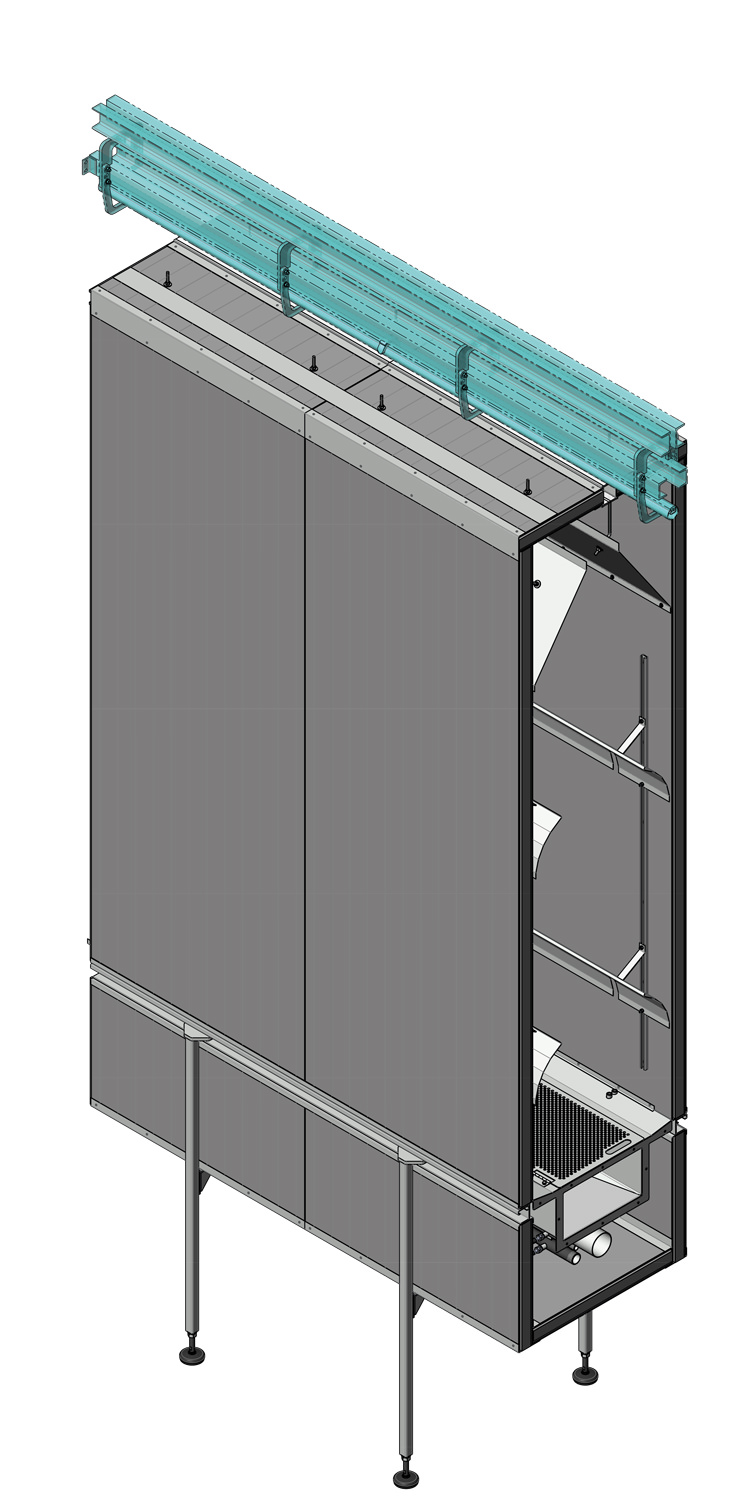

SCM-CT-240-B – Basic module

Module length 2,400 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

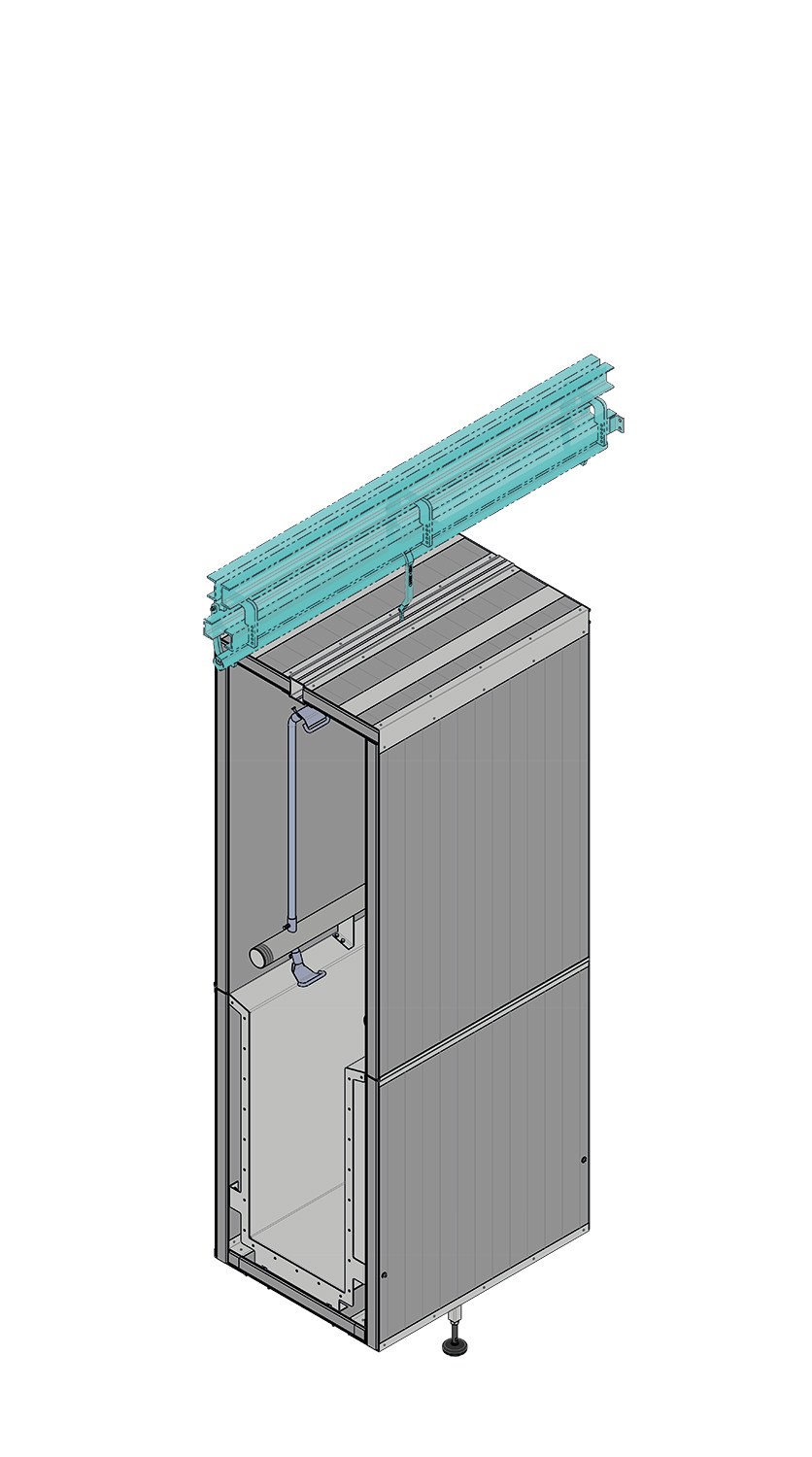

SCM-CT-150-I – Insertion

Module length 1,540 mm

Double-leaf swing door made of plastic

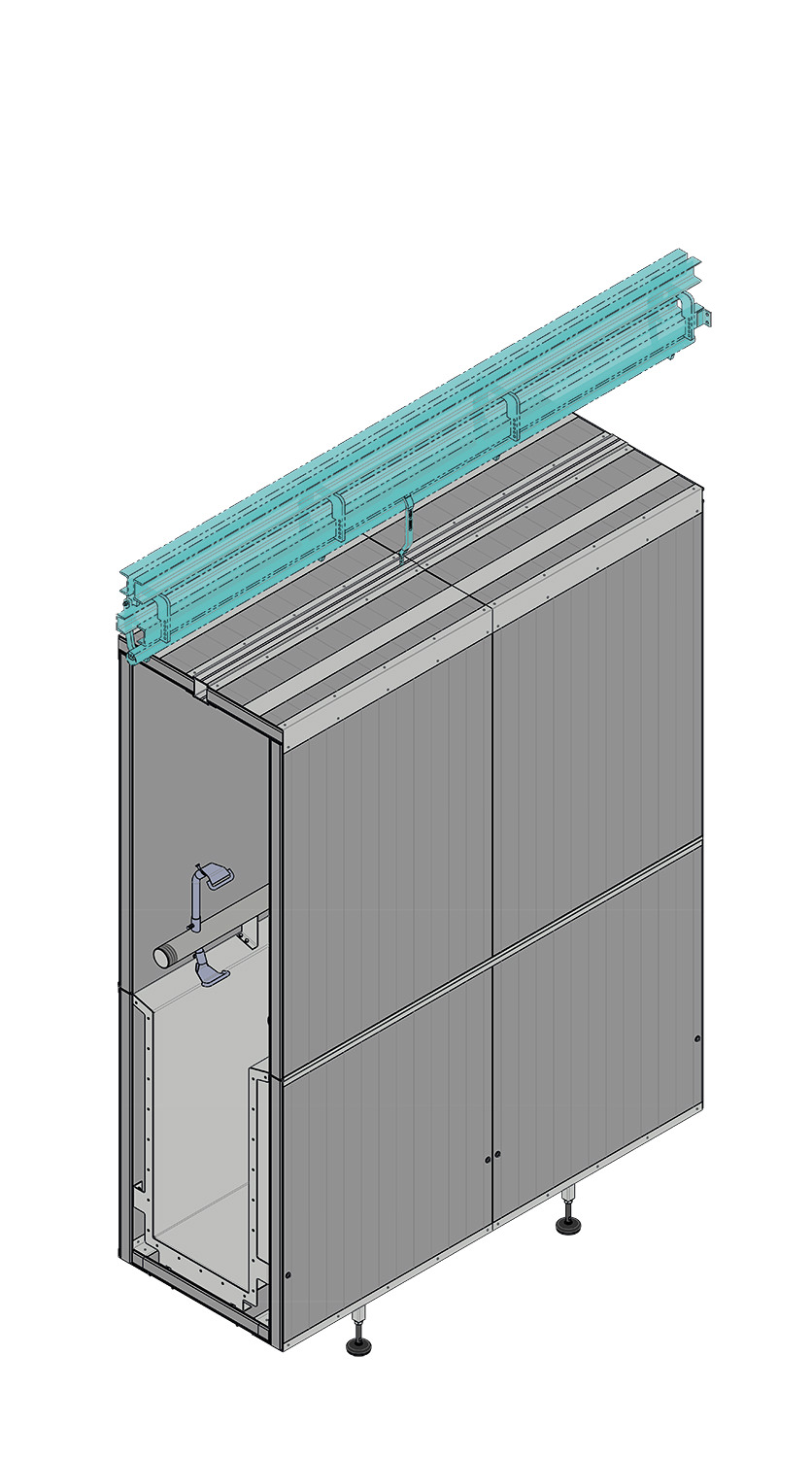

SCM-CT-150-D – Discharge unit

Module length 1,540 mm

Double-leaf swing door made of plastic

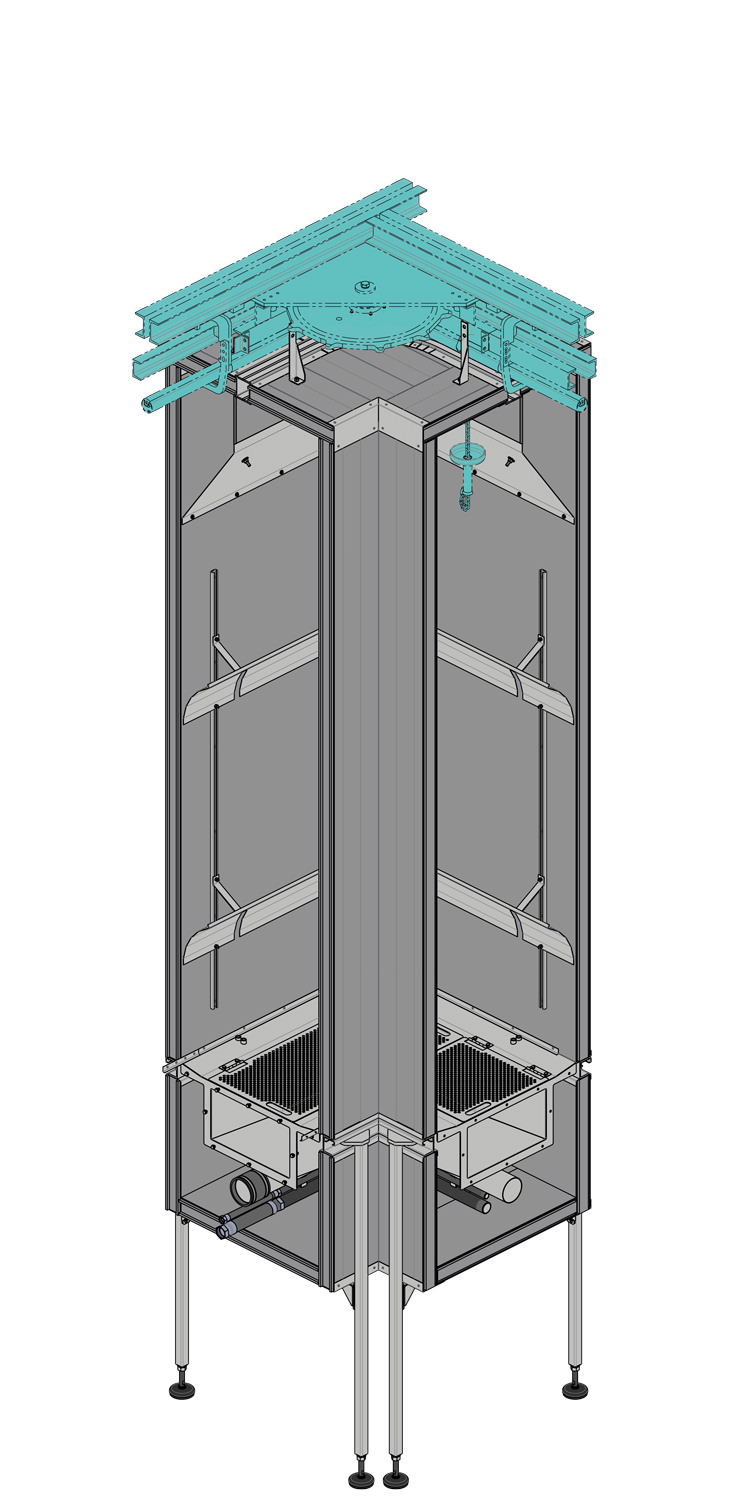

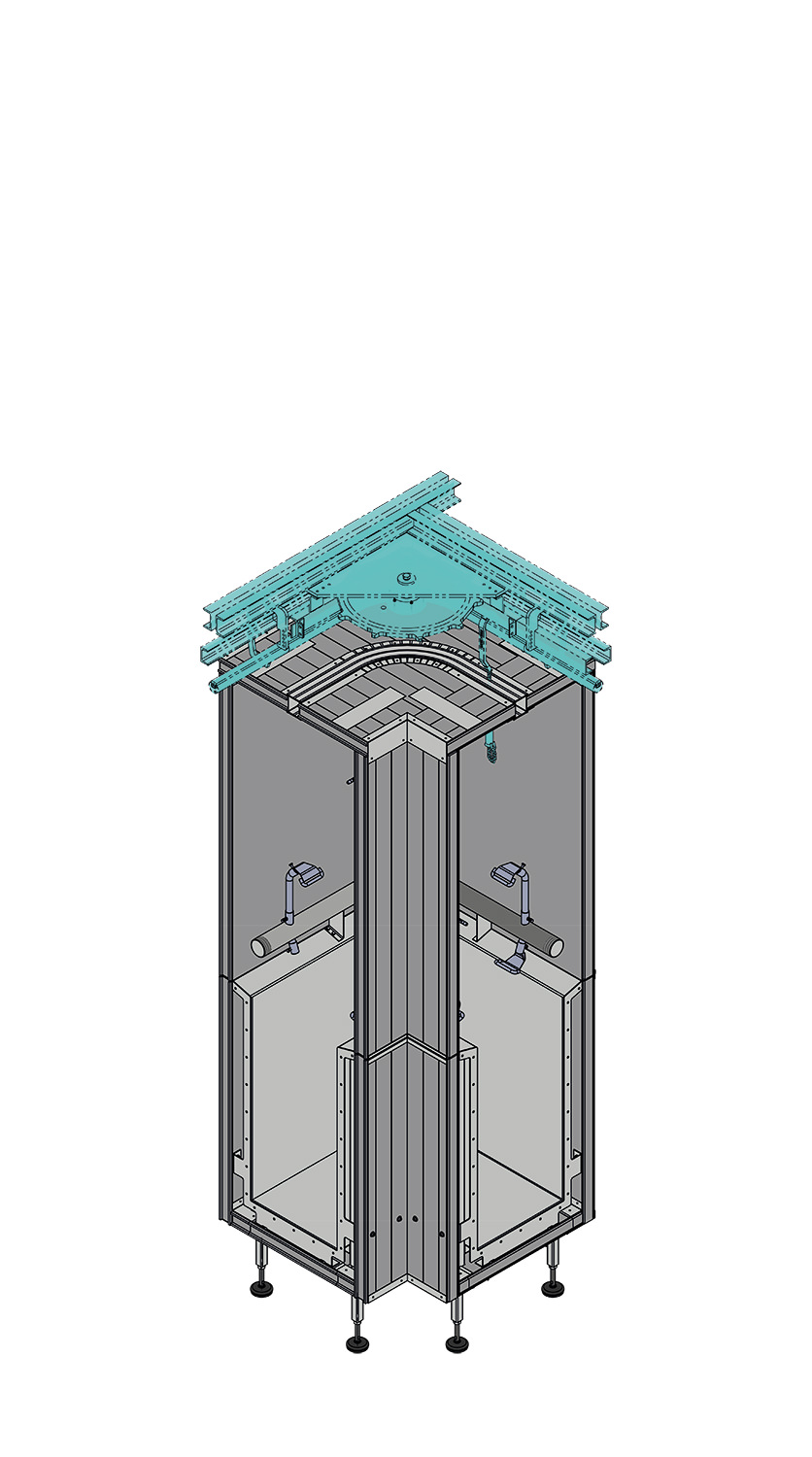

SMC-CT-90-C – Corner module

Module length 1,250 x 1,250 mm, 90 degrees

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

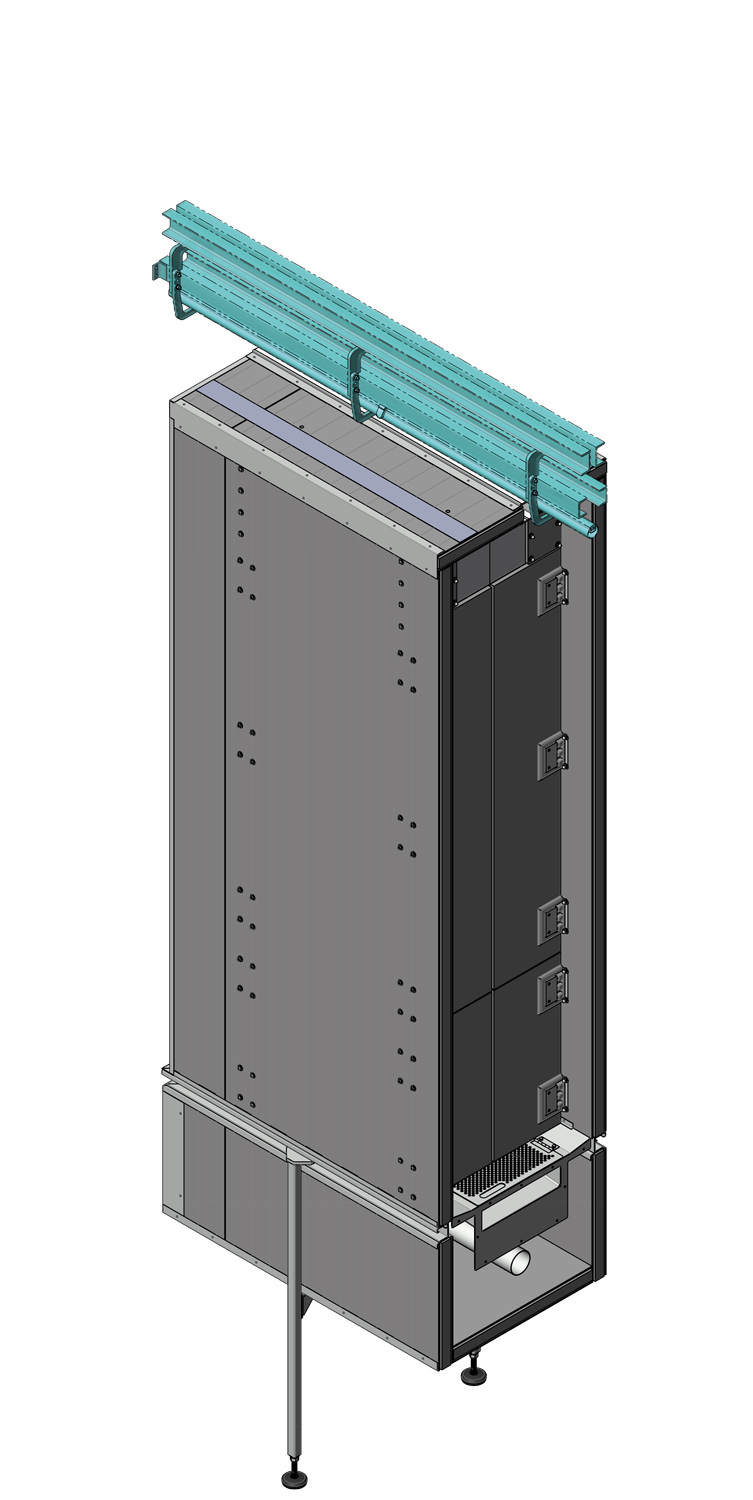

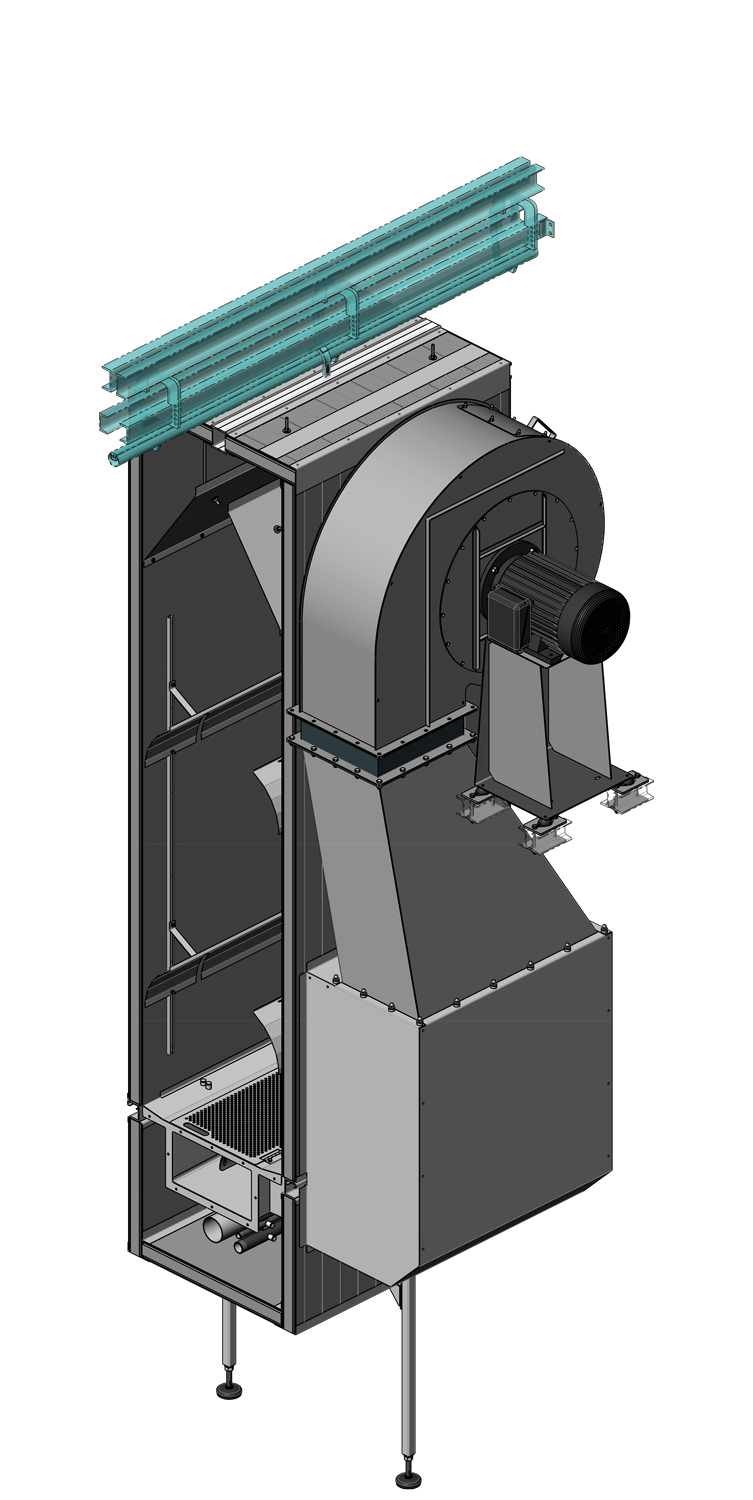

SCM-CT-120-V – Ventilation module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

Blower unit with blower motor

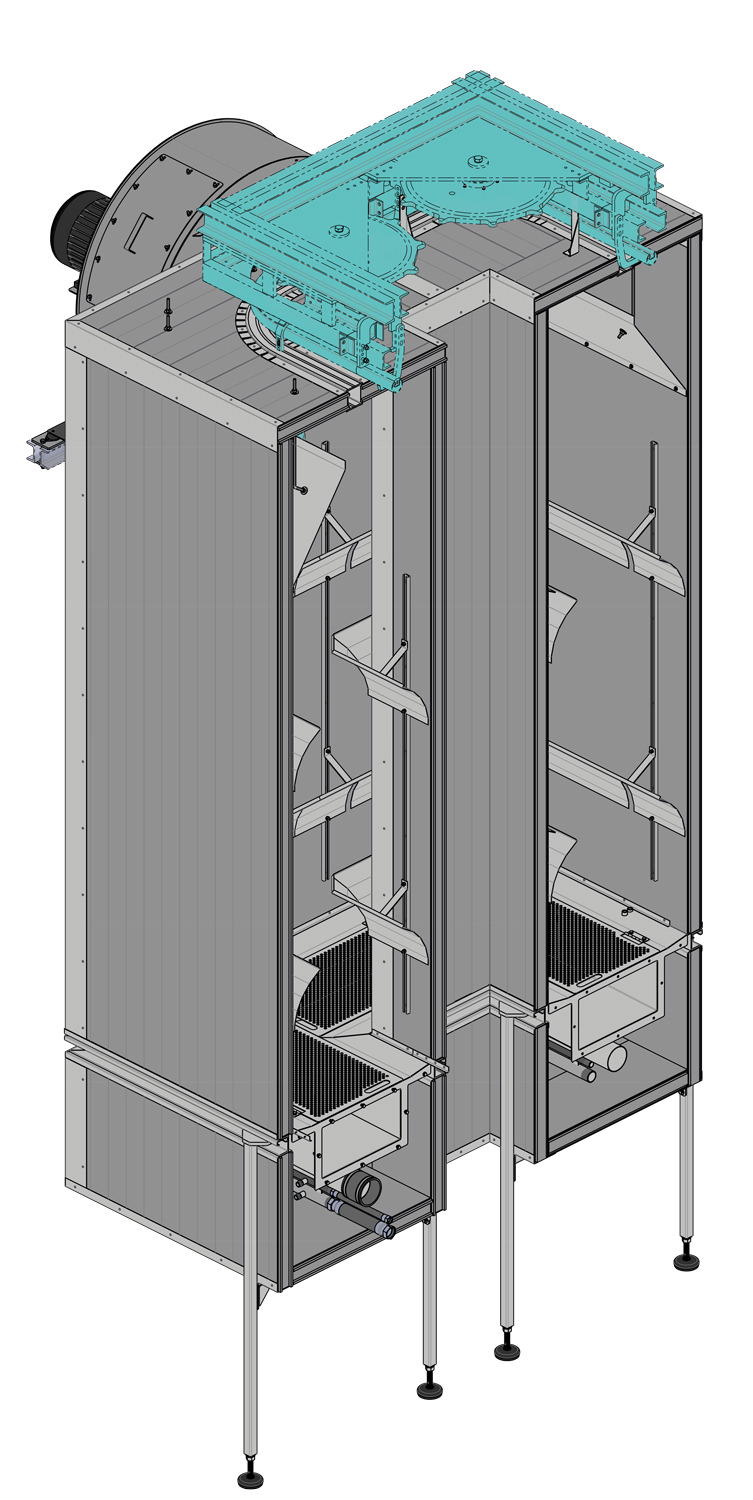

SMC-CT-240-C – Ventilation module

Module length 2,445 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

Blower unit with blower motor

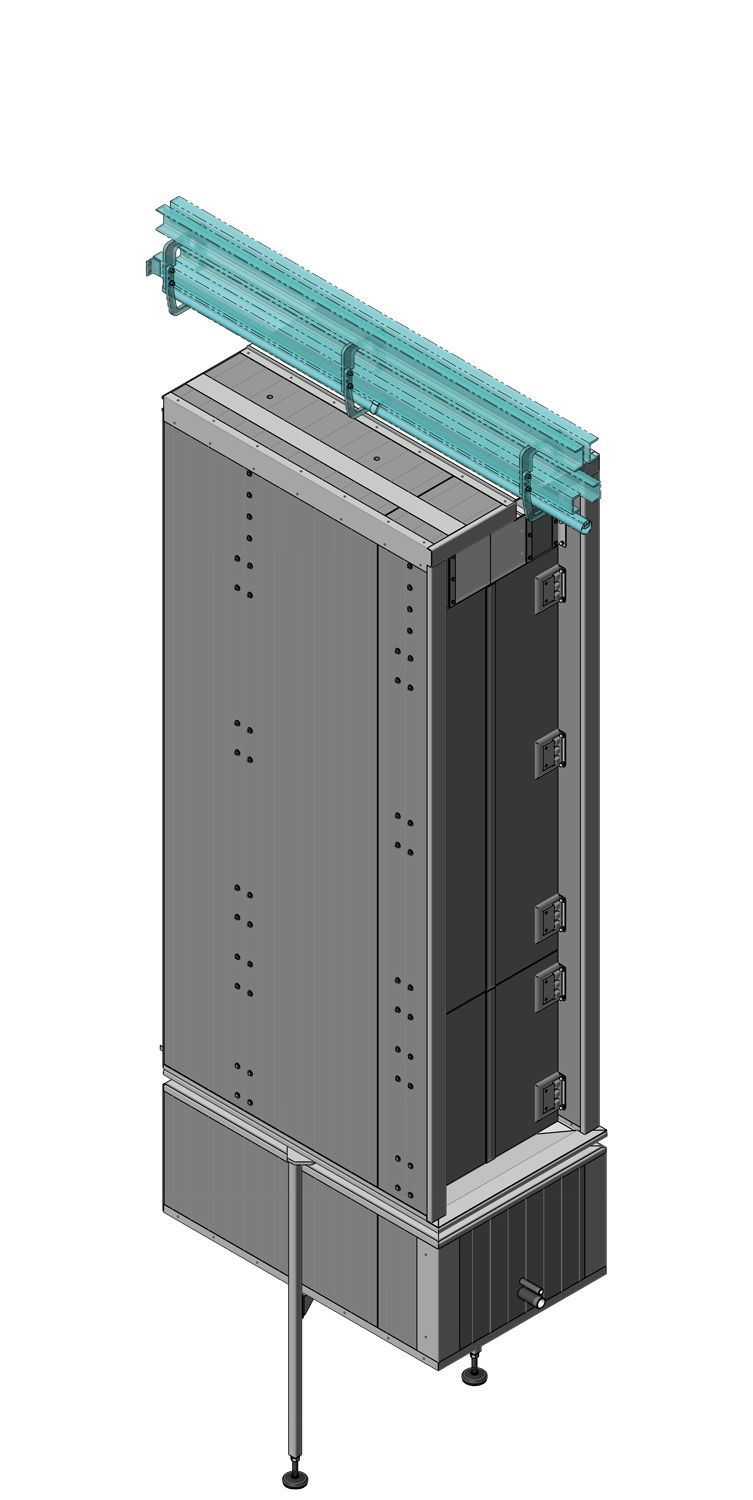

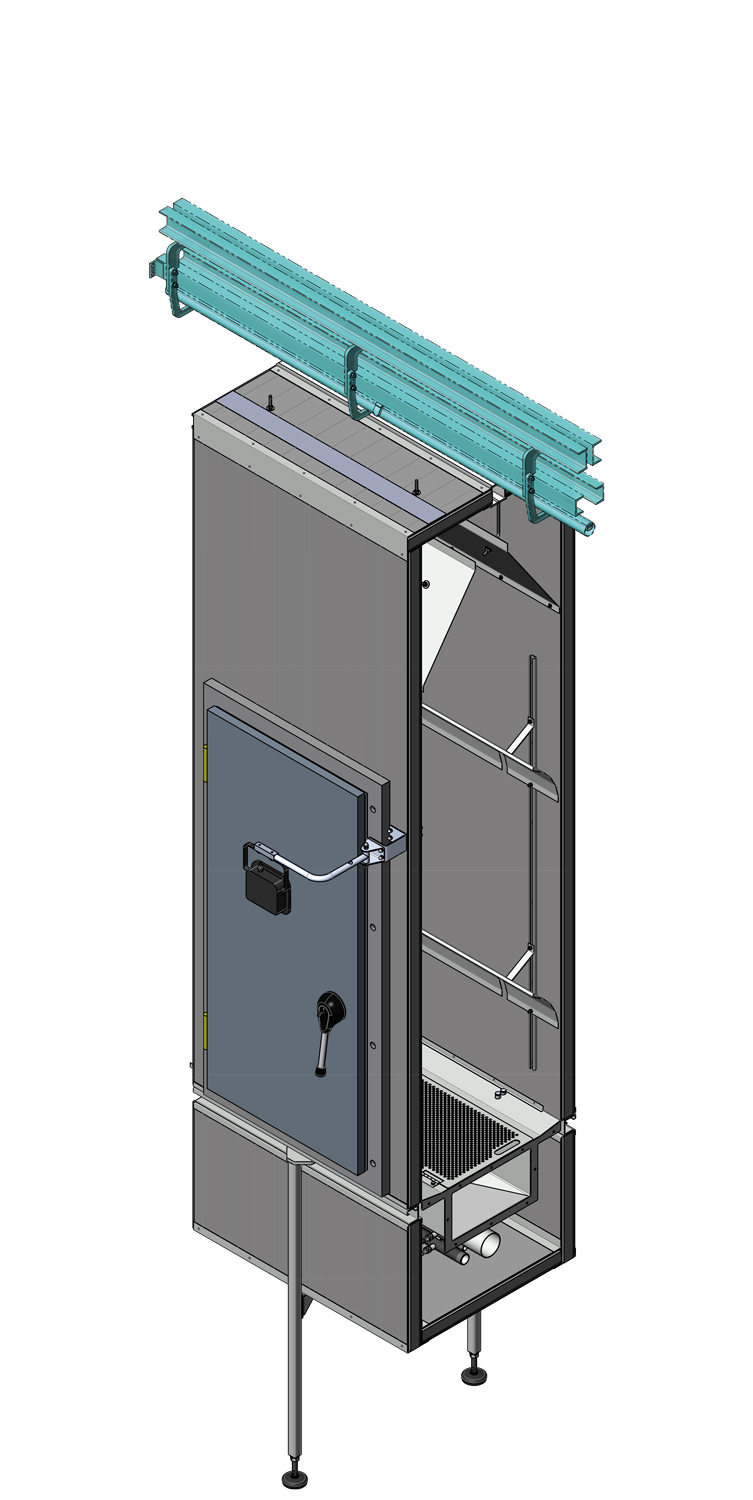

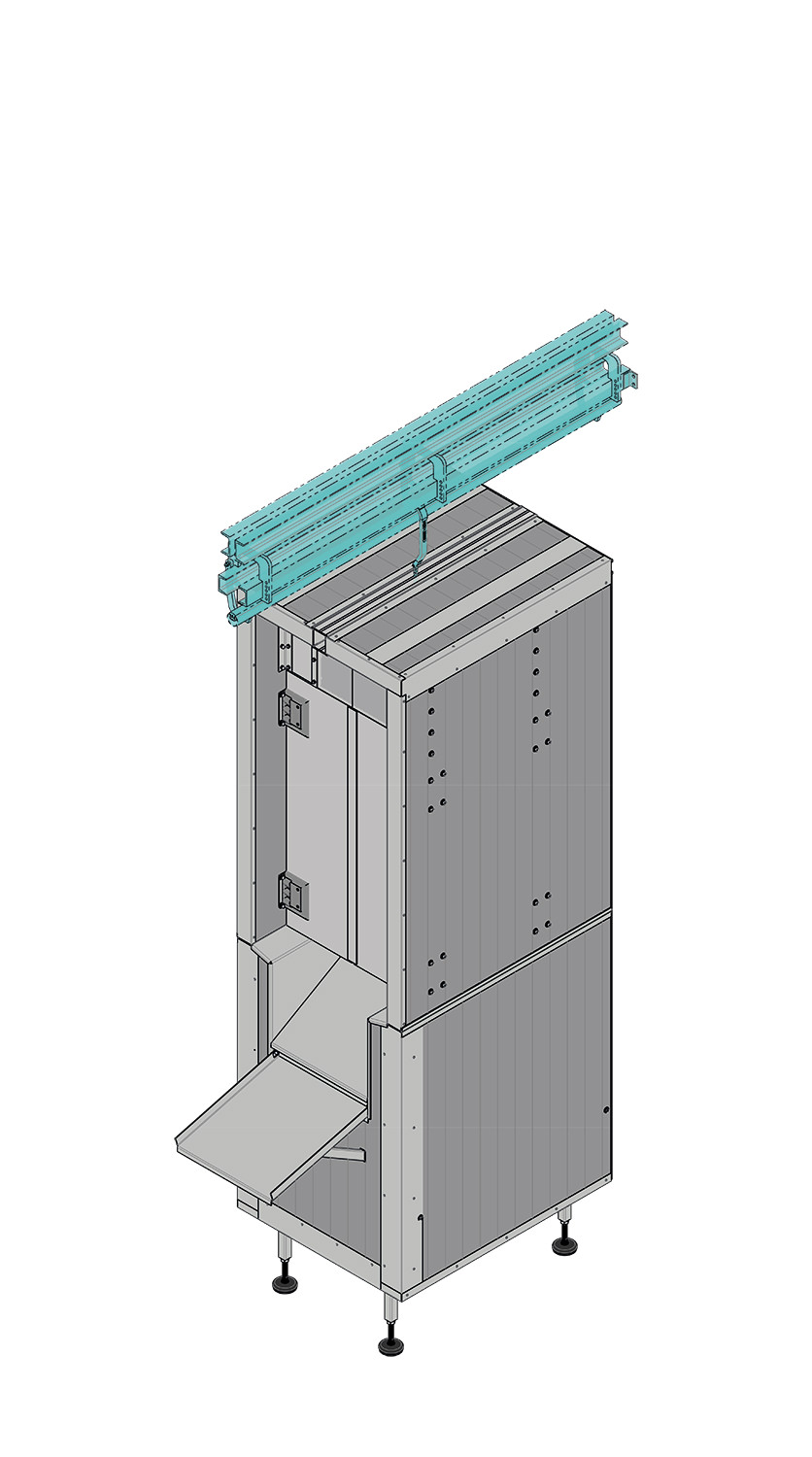

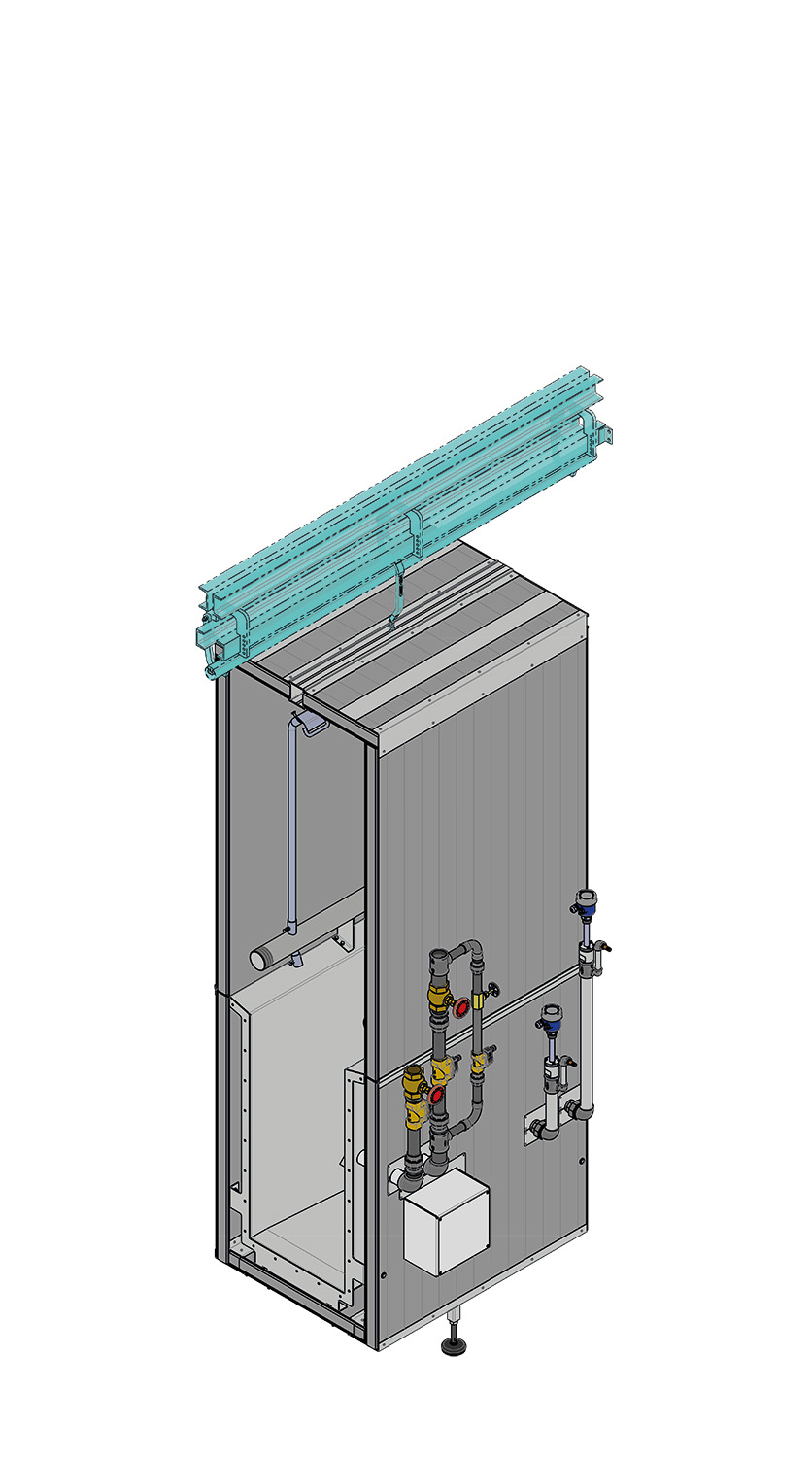

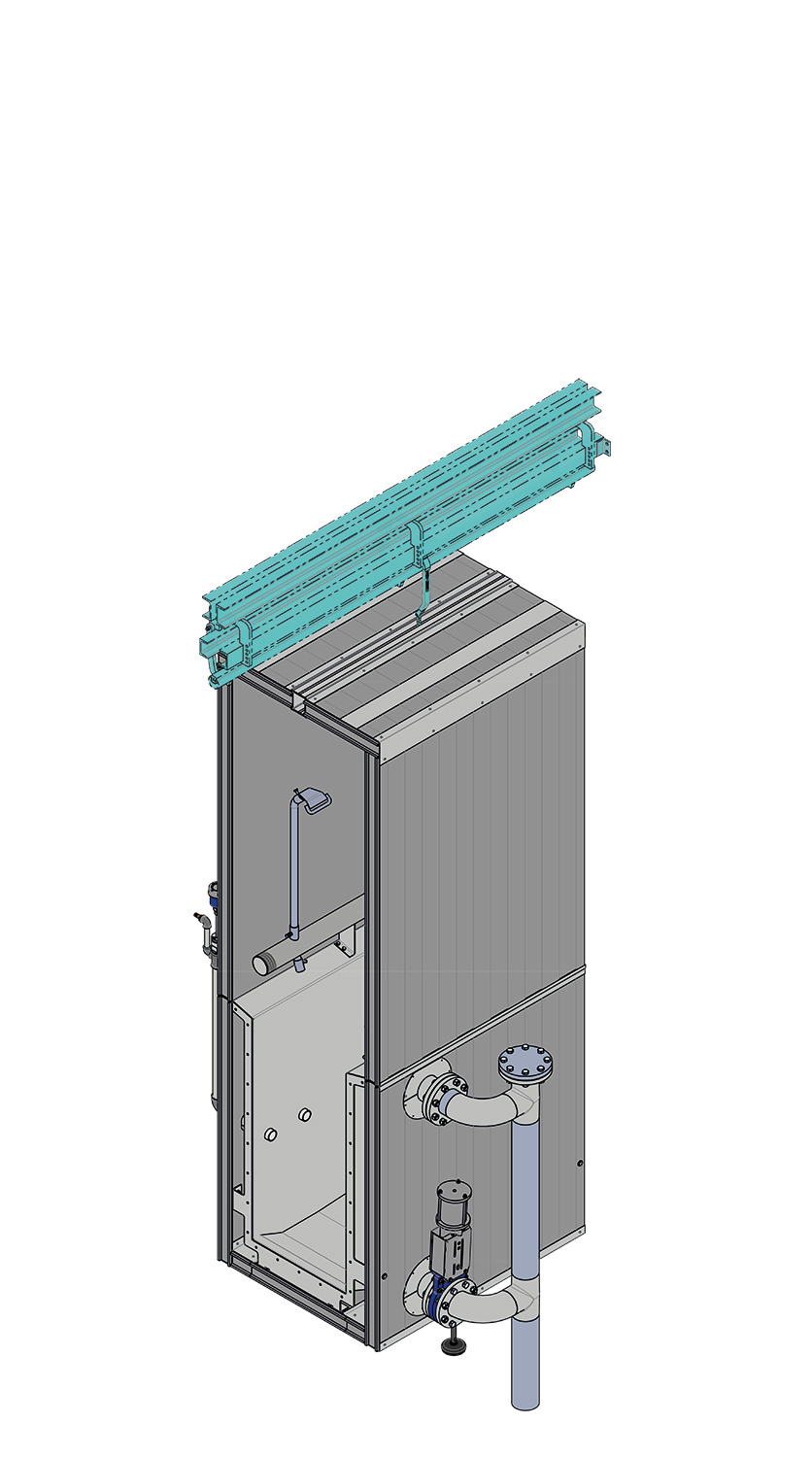

SCM-CT-120-M – Maintanced module

Module length 2,400 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

Entrance door made of insulating panel

Control terminal

JWE-BANSS sclading process achieves the highest scalding quality with the use of efficient technology.

Water scalding tunnel

| No. | Type | Module | Length | Width |

| 7060150002 | SMC-WT-120-B | Basic module | 1,200 mm | 945 mm |

| 7060150005 | SCM-WT-240-B | Basic module | 2,400 mm | 945 mm |

| 7060150007 | SMC-WT-150-I | Insertion | 1,200 mm | 945 mm |

| 7060150006 | SMC-WT-150-D | Discharge unit | 1,200 mm | 945 mm |

| 7060150003 | SMC-WT-120-PD | Pump module | 1,200 mm | 945 mm |

| 7060150009 | SMC-WT-120-S | Steam nozzle module | 1,200 mm | 945 mm |

| 7060150008 | SMC-WT-090-C | Corner module | 1,190 mm, 90 Degrees | 1,190 mm |

| 7060150004 | SMC-WT-120-F | Function module | 1,200 mm | 945 mm |

| 7060150011 | SMC-WT-120-F | Function module | 1,200 mm | 945 mm |

| 7060150010 | SMC-WT-120-M | Access module with pedestal | 1,200 mm | 3.510 mm |

Specifications

Brewing water tank made of hygienic frame construction of sheet metal and profile parts, stainless steel 1.4301

Insulating panel 80 mm wide, covered with

Height-adjustable feet

Control:

Stainless steel operating housing, incl. HMI display and operating elements

Stainless steel terminal box housing, incl. all necessary control components

Siemens S7 control

Mainsvoltage 400 V - 50 Hz

Control voltage 24 V / DC

Total power 5.5 KW

Protection class IP54

SMC-WT-120-B – Basic module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

SMC-WT-240-B – Basic module

Module length 2,400 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

SMC-WT-150-I – Insertion

Module length 1,200 mm

Double-leaf swing door made of plastic

Inlet chute made of stainless steel sheet 1.4301

SMC-WT-150-D – Discharge unit

Module length 1,200 mm

Double-leaf swing door made of plastic

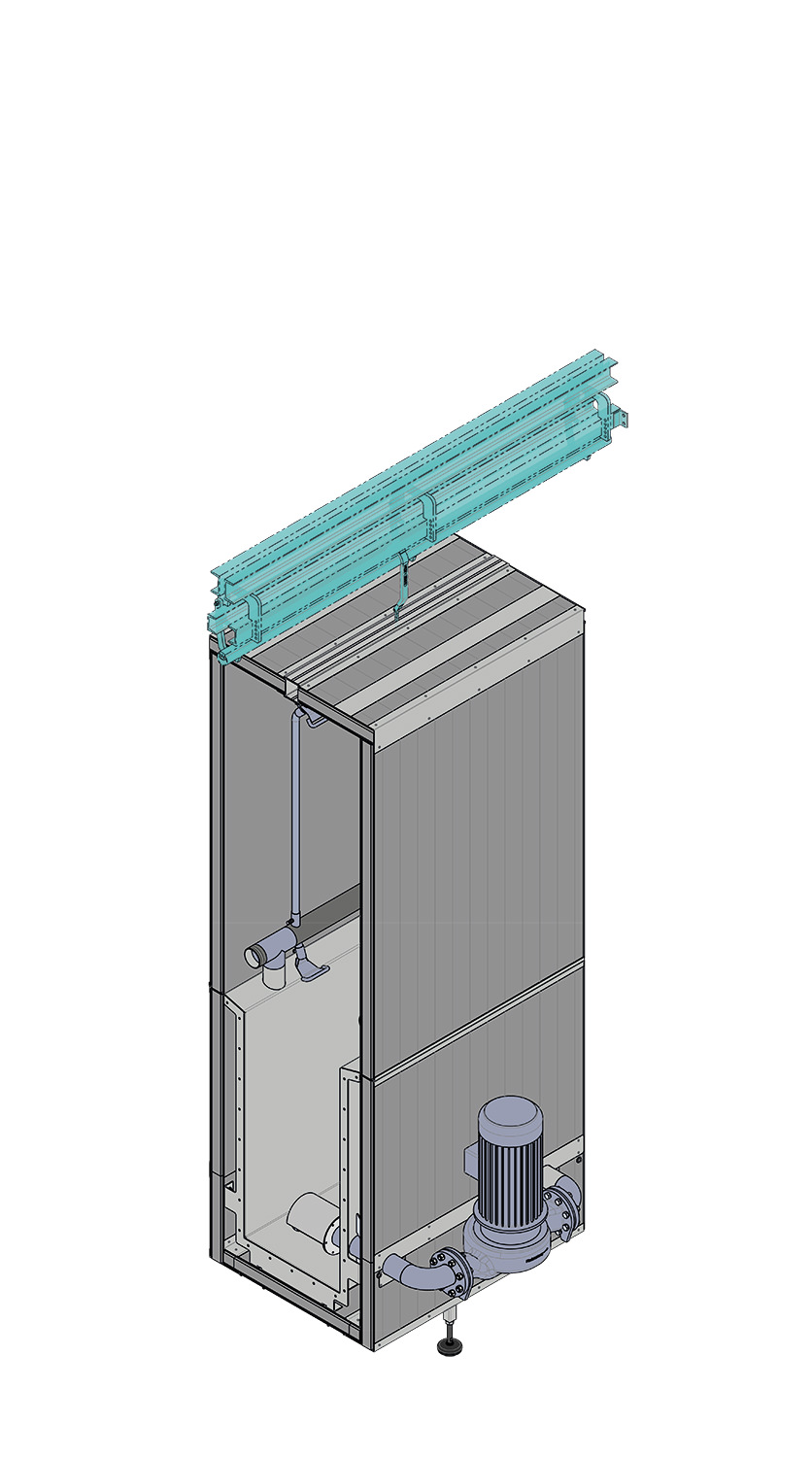

SMC-WT-120-PD – Pump module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

Circulating pump

SMC-WT-120-S – Steam nozzle module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

Steam connection

Steam control valve

SMC-WT-090-C – Corner module

Module length 1,190 x 1,190 mm, 90 degrees

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

SMC-WT-120-F – Function module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

SMC-WT-120-F2 – Function module

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

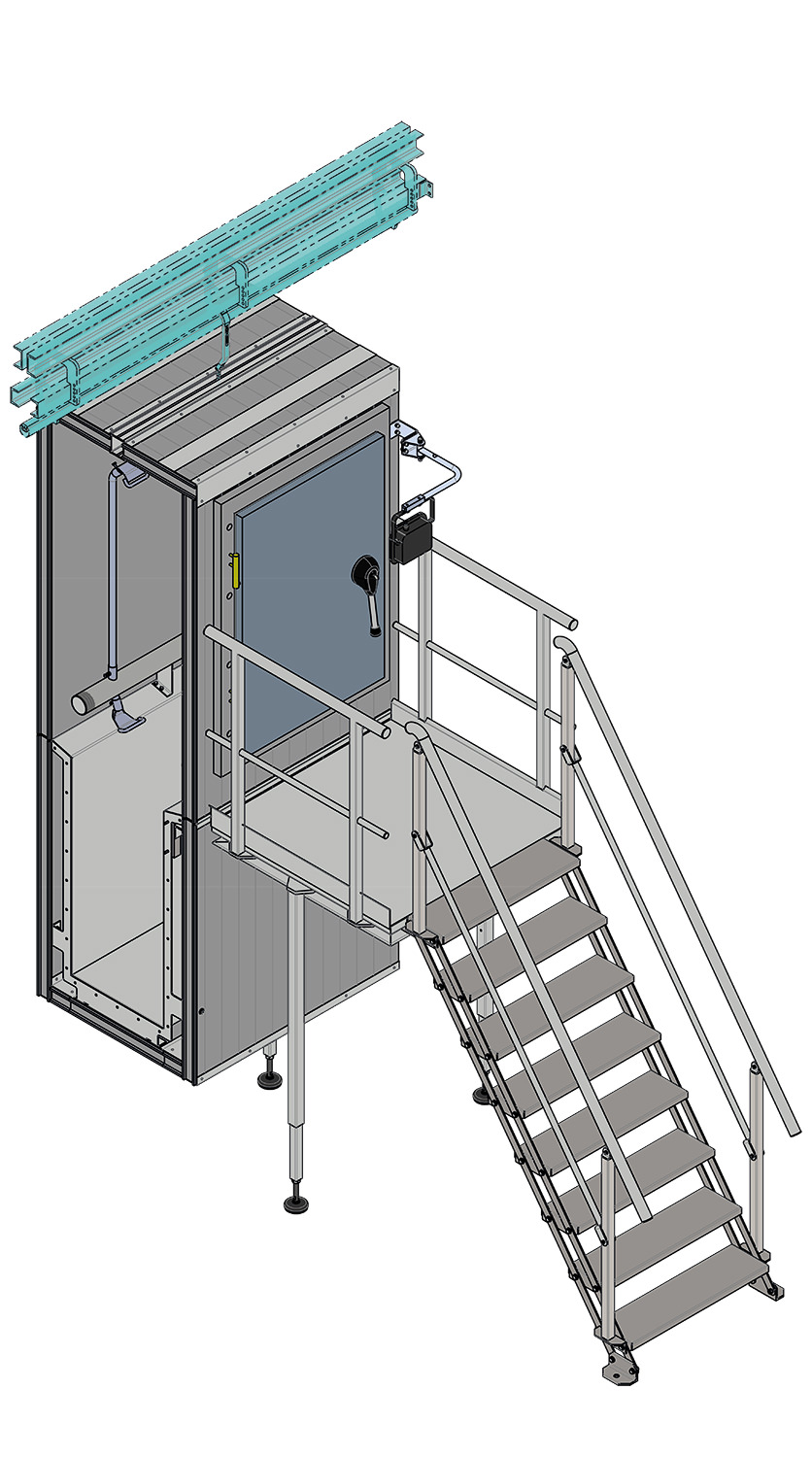

SMC-WT-120-M – Access module with pedestal

Module length 1,200 mm

Supply line made of stainless steel pipe

Integrated spray pipes equipped with special spray nozzles

Entrance door made of insulating panel

Control terminal